× close

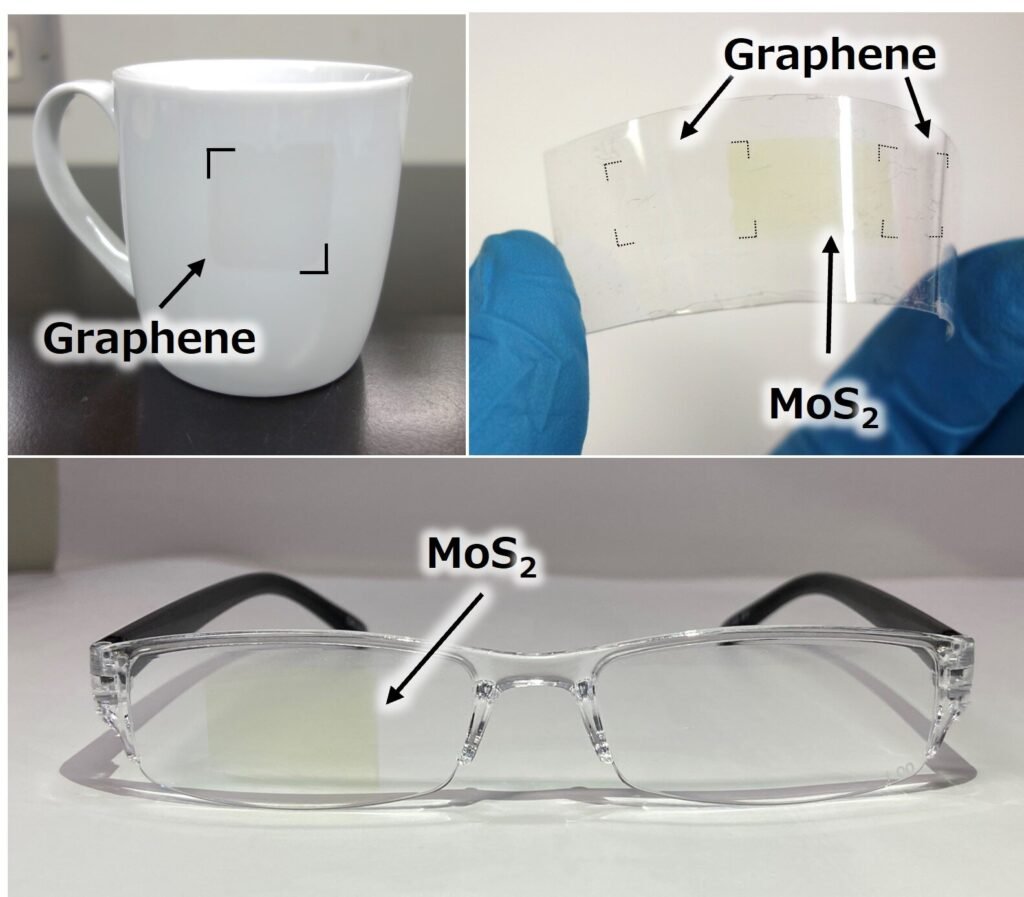

The newly designed UV tape can transfer 2D materials such as graphene and transition metal dichalcogenides to a variety of substrates including silicon, ceramic, glass, and plastic.Credit: Kyushu University Ago Laboratory

Materials only atom thick, known as two-dimensional (2D) materials, are set to revolutionize future technologies, including the electronics industry. However, the commercialization of devices containing 2D materials faces challenges due to the difficulty of transferring these extremely thin materials from the manufacturing site to the device.

Now, a research team from Kyushu University, in collaboration with Japanese company Nitto Denko, has developed a tape that can be used to attach 2D materials to a variety of surfaces in an easy and user-friendly way. It was discovered that published in nature electronics February 9, 2024.

“Transferring 2D materials is usually a highly technical and complex process. The materials are easily torn or contaminated, significantly reducing their inherent properties,” said lead author Kyushu University Global Innovation Center. Professor Hiroki Ago says: “Our tape provides a quick and easy alternative and reduces damage.”

The researchers first focused on graphene. Made from thin sheets of carbon atoms, graphene is strong, flexible, light, and has high thermal and electrical conductivity. It was called a “wonder material” at the time of its discovery, with potential applications in biosensing, anti-cancer drug delivery, aeronautics, electronics, and more.

“One of the main ways to make graphene is chemical vapor deposition, which involves growing graphene on a copper film. However, for it to work properly, the graphene must be separated from the copper and grown on an insulating substrate such as silicon. It needs to be transcribed into a computer,” Professor Ago explains.

“To do this, we place a protective polymer on top of the graphene and use an etchant such as acid to remove the copper. After pasting onto a new substrate, we dissolve the protective polymer layer with a solvent. The process is expensive, time-consuming, and can cause defects on the graphene surface or leave traces of the polymer. ”

Professor Ago and his colleagues therefore aimed to provide an alternative method to transfer graphene. Using his AI, they developed a special polymer tape called “UV tape” whose attraction to graphene changes when exposed to UV light.

× close

Researchers from Kyushu University and Nitto Denko have developed a tape whose two-dimensional material’s “stickiness” changes when exposed to ultraviolet light.Credit: Kyushu University Ago Laboratory

Before exposure to UV light, the tape has strong adhesion to graphene, allowing it to “stick.” However, exposure to UV changes the atomic bonds, reducing the level of adhesion to graphene by about 10%. The UV tape will also become a little harder, making it easier to remove. Taken together, these changes make it possible to peel the tape off the device substrate while leaving the graphene intact.

The researchers also developed a tape that can transfer two other 2D materials. One is white graphene (hBN), an insulator that he says acts as a protective layer when stacking 2D materials, and the other is transition metal dichalcogenide (TMD), a promising material for next-generation semiconductors. .

For more information:

Two-dimensional material that can be instantly transferred using tape with adjustable adhesive strength. nature electronics (2024). DOI: 10.1038/s41928-024-01121-3