Nearly all of the world’s supply of minerals essential to semiconductor manufacturing comes from a small town in the foothills of the Blue Ridge Mountains. hurricane helen.

Spruce Pine, North Carolina, is without running water or electricity more than a week after Helen struck the town of 2,200 people. Roads and railways within and outside the area are badly damagedAccording to local officials.

Spruce Pine mines produce the world’s purest quartz and play a central role in chip manufacturing.

Now, the city’s invaluable source of high-purity quartz is at risk, threatening to cripple the $600 billion global semiconductor industry.

The Spruce Pine natural disaster also highlights the continued instability of global supply chains, more than four years after COVID-19 made Americans acutely aware of our dependence on imported goods. I’m doing it.

Two companies, Sibelco and The Quartz Corp., extract high-purity quartz from spruce pine, refine it, and export it to manufacturing facilities primarily located in China and other parts of Asia.

Aerial view of a quartz mine in Spruce Pine, North Carolina, taken from an airplane on Monday, September 30, 2024.

Gary D. Robertson | AP

Much of the refined, high-purity quartz is used to create vessels called crucibles. This container holds the silicon as it is melted and transformed into wafers from which semiconductors are manufactured.

But mining, refining and shipping are all on hold for now.

Both Sybelco and Quartz were forced to shut down operations on Sept. 26 due to a storm that dumped more than 2 feet of rain on Spruce Pine, according to the National Weather Service.

Both companies have not yet decided when they will resume normal operations.

“The Spruce Pine region has been particularly hard hit. In response to these challenges, we have temporarily suspended operations at our Spruce Pine facility,” Sybelco said in a Sept. 30 statement. .

Quartz said in a statement on Oct. 1 that it has “no estimate” of when it will be able to resume operations.

Experts say the challenges posed to the semiconductor industry by the long-term disruption of the Spruce Pine mine cannot be overstated.

“This is currently the only factory in the world serving the entire semiconductor industry,” said TECHCET CEO Rita Shon Loy, who has studied the quartz supply chain for more than 20 years. ” he said. “If something were to happen at these mines, the entire industry would be on alert. There’s nothing else that can be done.”

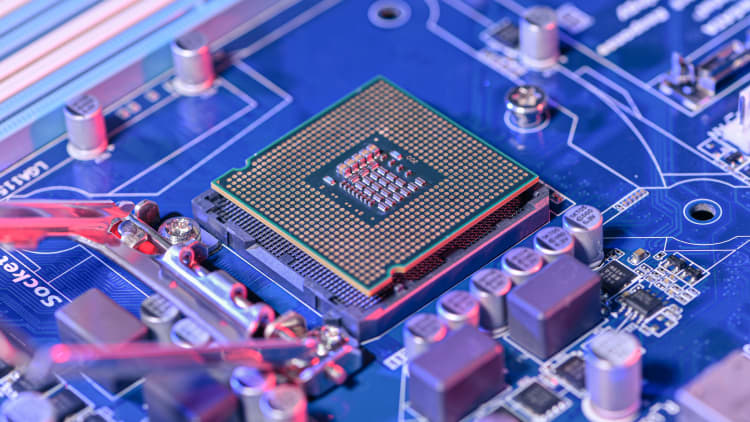

Epitavi | iStock | Getty Images

Experts say what happens next is a two-part question. First, operators must determine whether there was any damage to the quartz mine itself or to the equipment the company uses to extract or refine the mineral.

If mining operations are able to resume, a second question is how the companies will transport the refined crystals to export markets, given the state of some of Western North Carolina’s infrastructure.

TECHCET expects that it could take four to six weeks for both companies’ operations to operate at full throttle again. But given that both companies rely primarily on trucking to transport minerals, Shon Roy said that prediction depends on whether roads reopen.

However, early signs indicate that transportation infrastructure will require major restructuring.

“The roads are gone,” said Spencer Bost, executive director of Downtown Spruce Pine, a nonprofit affiliated with the city. In some areas, “roads no longer exist,” he said.

When it comes to power, Bost said, “It’s not like the power lines are down. The poles are gone.”

However, there are still two rays of hope for the semiconductor industry.

The first is that they likely have stockpiles of high-purity quartz for components to help create. That could give the industry two to three months while Spruce Pine recovers from Helen, Shon Roy said.

Satellite photo shows flooding of the North Toe River and Market in the aftermath of Hurricane Helen in Spruce Pine, North Carolina, USA, October 2, 2024.

Maxar Technologies | via Reuters

The semiconductor industry is emerging from the recession, but demand is quite soft, Shonroy said. Additionally, most companies have been holding more inventory since the pandemic.

“That will help ease delays in restarting these power plants,” Shonroy said.

Another benefit: Crucibles made using quartz have a shelf life of about 300 to 400 hours, or about two weeks, before needing to be replaced, says Dustin Mulvaney, an environmental studies professor at San Jose State University. Masu. Solar energy product chain.

As a result, there could be some delay before chipmakers incur further damage.

“But once you have to replace the crucible, there can be some disruption,” Mulvaney said.

The longer it takes for Spruce Pine’s mining industry to restart, the greater the impact will be.

“A month’s delay is not bad,” Shonroy said. “The second month is getting difficult. The third month is when it becomes a real problem.”